ISO 13485 standard

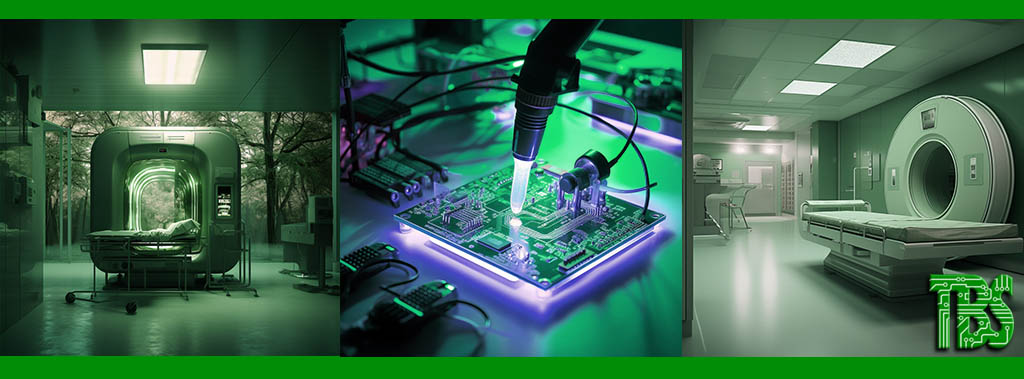

The ISO 13485 standard is the most widely used worldwide standard for companies that make medical devices.

It usually is part of a business’s broader quality process – ISO 9001

This helps businesses and their customers get consistently good-quality products and services.

– With ISO 13485 certification, medical devices are made, installed, and taken care of to the best standards.

– The certification helps companies show that they care about safety, quality, and being able to make medical devices well.

Costs go down with ISO 13485 approval because it gives a strong framework for controlling the supply chain and making things run more efficiently.

It helps companies meet the legal and regulatory requirements of the industry for making medical devices.

– The licence is recognised all over the world and shows that a business is good in the global market.

– In order to get ISO 13485 certification, you have to start with a consultation, make paperwork, get training, have a third-party audit, and get certified.

– During the certification process, ISO experts can help and give advice.

Getting ISO 13485 certification isn’t required, but it helps businesses keep up with worldwide standards and local rules.

– ISO 13485 certification helps makers of medical devices show that they care about quality and efficiency.

– How long it takes to get ISO 13485 certification depends on how big and complicated the business is. It can take anywhere from 4 to 12 months.

– For the CE mark, you don’t need ISO 13485 approval, but you do need proof of a quality management system.

Future information on ISO 13485 can be found at the ISO International Organization for Standardization